HSC® Coating is specifically engineered to control hot surface temperatures up to 176 °C / 350°F. It is lightweight and smooth in appearance. This is a water-borne system using a special acrylic blend with specific ceramic compounds to provide the non-conductive block against heat transfer without depending upon reflectivity. The coating will dry down on a cold surface by evaporation and can be aided in the dry down by adding heat to the environment. If the surface is already heated, the dry-down process will take care of itself without additional steps required.

HSC® Coating is water-borne to offer a non-flammable and non-toxic formula for medium heat surface applications over standard steam pipes, oven wall construction and other hot surfaces. This coating was designed for applications whose temperature exposures falls below that which requires HPC® COATING ( up to 572°F / 300°C). HSC® Coating is more easily applied for a smoother finish.

HSC® Coating can be applied over metal, concrete, wood or all surfaces not glazed or containing polypropylene (having no pores).

Commercial and Institutional Steam Efficiency: Checklist for Getting Management Approval

Research on Wrap Insulation vs Pipe Coating By Dr. Ir. Aniello Palmieri

|

ROCKWOOL/FIBERGLASS WITH METAL JACKET |

HSC® COATING |

|

INSTALLATION |

|

| Must shut down operation to install | HSC® COATING is installed without a shutdown |

|

INSULATION EFFECTIVENESS |

|

| Deteriorates rapidly and loses insulating value when moisture is present plus elbows & valves can not be wrapped effectively so heat losses are significant in these areas | Non-Deteriorating and does not lose insulating value when moisture is present plus can be sprayed on elbows and valves reducing the significant heat losses through these areas |

|

CRACK DETECTION |

|

| When a pipe cracks, the entire Jacket and RockWool or Fiberglass must be removed and repaired which requires downtime | When a pipe cracks, it can be inspected directly on the spot without removal and easily repaired by spraying or trowel application |

|

CONDENSATION – DEWPOINT CHART OR DEW POINT CALCULATOR |

|

| High due to the air trapping characteristics of RockWool/Fiberglass | No condensation due to complete surface bond |

|

CORROSION UNDER INSULATION ( CUI ) |

|

| High due to condensation problem | No condensation thus no corrosion |

|

REPAIR |

|

| Must shut down operation to repair | No repair is necessary for HSC® COATING |

|

MAINTENANCE COSTS |

|

| High due to frequent maintenance required for condensation & corrosion control plus high down time, labour and material costs | Low as HSC® COATING is directly sprayed without plant shut down plus the labour and material cost are much lower |

|

LIFE SPAN |

|

| Lasts about 6 months |

Several years |

Note : The cost comparison between Rockwool/Fiberglass vs. HSC® COATING coating for hot pipes should be made with respect to the total costs. The total costs include: material costs, installation costs, repair costs, frequency of downtime, maintenance costs, labour costs and life span. When all these costs are combined, HSC® COATING coating is superior to Rockwool/Fiberglass insulation as evident in the above comparison.

BTU LOSS CALCULATION

( These calculations are courtesy of Georgia State University )

In order to calculate cost savings by BTU loss prevention ( the Stefan-Boltzmann law ), there are several variables that need to be determined such as the radiating area, the emissivity of the radiating body, the radiating temperature, the surrounding temperature, etc.

Once these variables are known then the CALCULATION of BTU loss per hour can be performed.

The total BTU loss can then be translated into DOLLARS!

Example: 1,000,000 Btu's = 1,000 CFT of Natural Gas = 1 GJ of electricity,

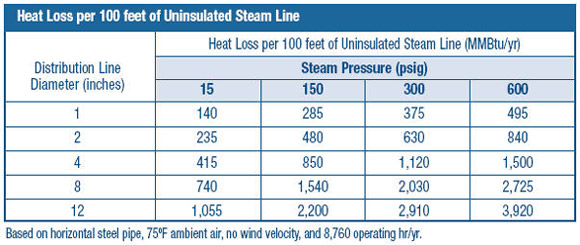

to assist in the calculation of the radiating area of a pipe here is a chart.

Introduction

Uninsulated steam distribution and condensate return lines are a constant source of wasted energy. Insulation can typically reduce energy losses by 90% and help ensure proper steam pressure at plant equipment. Any surface over 120°F should be insulated, including boiler surfaces, steam and condensate return piping, and fittings.

Insulation frequently becomes damaged or is removed and never replaced during steam system repair. Damaged or wet insulation should be repaired or immediately replaced to avoid compromising the insulating value. Eliminate sources of moisture prior to insulation replacement. Causes of wet insulation include leaking valves, external pipe leaks, tube leaks, or leaks from adjacent equipment.

Example: In a plant where the value of steam is $4.50/MMBTU, a survey of the steam system identified 1,120 feet of bare 1-inch diameter steam line, and 175 feet of bare 2-inch line both operating at 150 psig. An additional 250 feet of bare 4-inch diameter line operating at 15 psig was found. From the table, the quantity of heat lost per year is:

1-inch line: 1,120 feet x 285 MMBTU/yr per 100 ft = 3,192 MMBTU/yr

2-inch line: 175 feet x 480 MMBTU/yr per 100 ft = 840 MMBTU/yr

4-inch line: 250 feet x 415 MMBTU/yr per 100 ft = 1,037 MMBTU/yr

Total Heat Loss = 5,069 MMBTU/yr

The annual operating cost savings from installing 90% efficient insulation is:

0.90 x $4.50/MMBTU x 5,069 MMBTU/yr = $20,530

If a durable protective finish is required because of the surrounding environment, such as physical, mechanical abuse or over pipes subject to vibration, apply as follows. After the last coat is applied but before it dries, wrap polyester or fiberglass mesh around the pipe with the edges slightly overlapping to provide complete coverage. Allow this to dry. Topcoat with SUPERTHERM ®.

For exterior applications subjected to WEATHERING apply SUPERTHERM ® at 9 m2 95 f2 per gallon giving 16 mils WFT or 250 microns 10 mils DFT or SP LIQUID MEMBRANE ® Water based aliphatic polyurethane at 18 m2 200 f2 per gallon at 8 mils WFT or 92.5 microns 3.22 mils DFT. Allow to dry and cure over night.

For resistance from CHEMICALS apply ENAMOGRIP ® Solvent ( White or Coloured ) or RUSTGRIP ® at 18 m2 200 f2 per gallon at 8 mils WFT or 92.5 microns 3.7 mils DFT. Allow to dry and cure over night.

For applications with HIGH HUMIDITY or SUBMERGED UNDER WATER allow the HSC® COATING to dry then apply EPOXOTHERM ® at 9 m2 100 f2 per gallon giving 16 mils WFT or 312.5 microns 12.46 mils DFT. The total system can be submerged under water in two days. The full cure for the EPOXOTHERM ® is 10 days but in two days it has cured enough to allow for submersion while it completes its curing cycle.

Superior Products International has been experimenting with and developing the uses of "insulation and fire protection" ceramics for over 15 years. This category of ceramic functionality is new to the engineering fields. Only in recent years has the idea of insulation been associated with this new breed of ceramics.

Superior Products International knew that this area had not been thoroughly explored before, nor had any extensive documentation been presented for this application. In contrast, many articles and studies have been devoted to the abrasion resistant ceramic compounds and how they can be used in manufacturing and industrial markets.

Insulative ceramics are completely different and separate from those used for abrasion resistance. No extensive studies have been performed to determine which ceramic compounds, either natural or manmade would be best suited for eliminating heat transfer. Some studies have acknowledged the "reflection" of heat by mere radiation of sunlight but since very limited study has been performed, it was thought that reflection was all that this new category of ceramic could provide.

Superior Products International initially worked in the early 1990's with the aid of the ceramic engineers at the Marshall Space Center Laboratories, and it was discovered that no real research had been performed across the broad spectrum of possible ceramic compounds in order to determine the scope of ceramics stopping or slowing "heat conduction" rather than merely radiant heat reflection. It was also decided that Superior Products International would continue the R&D work over the next several years to discover the possibilities of this new design of ceramics. An extensive search was organized and begun to locate all possible types of ceramics compounds in the world market for trial-and-error testing. A system was designed to take each compound through a series of heat conduction tests to find its ability to stop heat conduction. More than 1,500 compounds were received and tested. From this R&D period, eight different compounds were identified as having the ability not only to catch and throw heat away from their surfaces in a manner similar to reflection but also to control heat transfer via conduction.

Superior Products International chose three of these ceramic compounds to develop its insulation coating called SUPERTHERM ®. A fourth ceramic was added in 2000 as part of our continued research in controlling heat transfer. This is a thin film coating that will protect against heat migration equal to six inches of fiberglass batt insulation when applied over surfaces facing the heat source. SUNSHIELD ® is inferior to SUPERTHERM ® but is still superior to any of the cheap imitations on the market.

SUNSHIELD ® is less expensive because the Fire ceramic resistance and urethane toughness have been left out. SUNSHIELD ® does have the same dual acrylics and similar ceramic insulation package. EPOXO THERM ® likewise has a similar ceramic insulation package but in an Epoxy carrier. Epoxies are required for application to wet substrates such as in the case of extreme condensation.

Seven of the ceramic compounds were also chosen to work in combination with one another in high heat situations. HPC® COATING® and HSC® COATING ® were developed to capture surface heat and stop thermal transfer via conduction. As with all of our protective coatings, each one is specifically engineered to solve a particular problem under a wide variety of application requirements and conditions.

Unless Superior Products provides a written warranty of fitness for a particular use, Superior Product's sole warranty is that the product, as supplied, will meet the current sales specifications and is specific only to return of product found to be defective upon opening of container within one year. Customer's exclusive remedy and Superior's sole liability for breach of warranty is limited to refund of the purchase price or replacement of any product shown to be other than as warranted and Superior Products expressly disclaims any liability for incidental or consequential damages.