header.jpg)

header.jpg)

| HPC® COATING is designed to control heat transfer for temperatures up to 932°F (500°C). It is lightweight and smooth in appearance after mixing. HPC® COATING is a water-borne system using a special acrylic/urethane blend with specific ceramic compounds to provide a non-conductive block against heat transfer. HPC® COATING offers a nonflammable/non-toxic formula for hot surface applications over standardsteam pipe or oven wall construction, but can be used for insulation of vessels well below freezing, after cured. The coating was designed to create a monolithic insulation system that can be sprayed over most surfaces and higher temperatures. It can be applied over metal,concrete, wood, gypsum, and most other substrates. SURFACE PREPARATION Surface must be clean from oil, tar, rust, grease, salts, and films.

The temperature of a pipe, valve, or tank cannot be determined by taking the exterior surface temperature where heat is released into the atmosphere. Surface temperatures will rise to match the temperature of the fluid or gas contained once the surface is coated and the heat is held back.MIXING

|

APPLICATION HPC® COATING must be applied by spray.

NOTE: For application over hot, flat steel surfaces,

Hot pipe Applications: Cold Surface Applications with operating temperature under 150°C:

Manufacturing or OEM Applications: Please contact SPI office. High-Heat System: CLEAN-UP EQUIPMENT Storage of Product: Store HPC® COATING between 40°F (5°C) and 120°F (49°C) |

The surfaces must be clean and dry before application. Loose or flaking old paints or corrosion must be removed from surface before applying. Surface must be clean of all residues and debris. Surfaces can be cleaned by power washing the surfaces ( SSPC - SP12 \ NACE No 5 ), sandblasted as a "brush off blast or sweep blast" ( SSPC - SP 7 \ NACE No 4 ), hand tool cleaned ( SSPC - SP 2 ) or power tool cleaned ( SSPC - SP 3 ).

FEATURES:

| Percent Solid: | 71% solids by volume |

| Weight | 5 pounds per gallon 47% solids by weight |

| Dry Times: | 5 - 10 minutes as primer at up to 80.2 mils WFT = 62.65 mils DFT @ 20 sq. ft. per gallon over hot surfaces then build up as needed. Allow 24 hours to set. Full dry by next day |

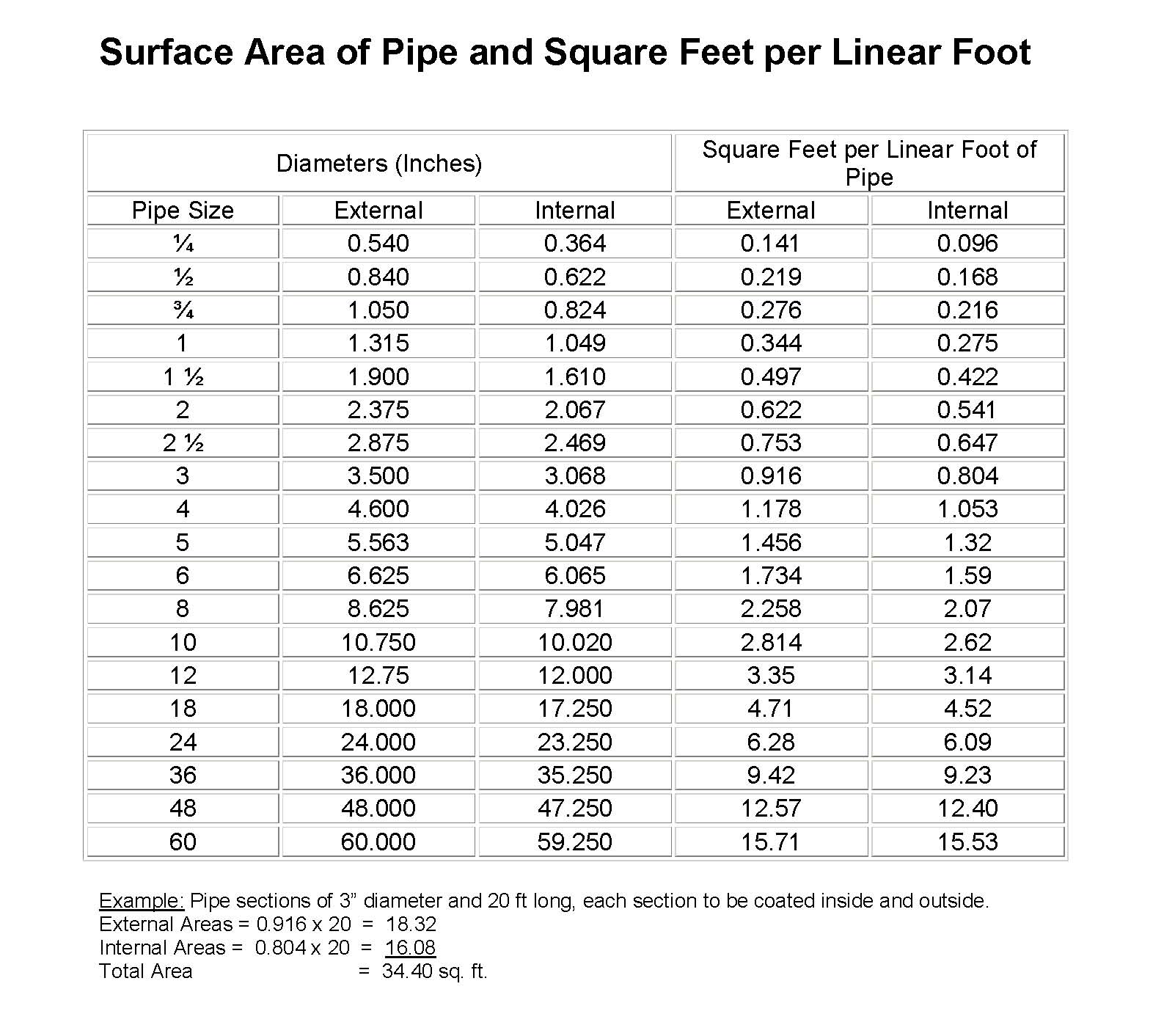

| Spread: | 22.4 sq. ft. per gallon

= 50 mils DFT as a primer coat 11.2 sq. ft. per gallon = 100 mils DFT as a build coat 5.61 sq. ft. per gallon = 200 mils DFT as a build coat 4.5 sq. ft. per gallon = 250 mils DFT as a build coat |

|

|

| Elongation: | 125% |

| pH | 8.5 - 9.0 |

| VOC | 15 grams per liter USDA Approved |

PRE-APPLICATION APPEARANCE AND PREPARATION OF HPC® COATING

QUESTION: After delivery and storage, the top of a pail of HPC Coating has swollen and expanded and appears too dry and chunky to use. Is it defective? What causes the swelling of the pail and the dryness?

ANSWER: HPC® COATING is a water-based, ceramic coating and is delivered in a 5 gallon pail. After the pail is sealed and stored, HPC Coating will gradually absorb and dissipate its own water over time. Some air pressure is created in the pail during this process and may cause the top of the pail to expand and swell. This absorption/dissipation process is commonly known as rheology and does not harm or adversely affect the use or performance of the coating.

| HPC - Before Mixing In Pail | Early Stage During Mixing in Pail |

Rheology occurs when a coating begins to set up because of non-activity. When the coating is stirred and water is added, the rheology allows the coating to relax and loosen and to return to its original consistency. After opening the pail, the top surface of HPC Coating may appear very dry and dusty with some cracking. As a result, the applicator may believe that HPC Coating idefective or too dry to use. This is not the case, and the appearance of HPC Coating will change dramatically upon proper mixing.

| Six Inch Dispersion Blade | Six Inch Dispersion Blade |

Stir HPC® COATING with a six inch (6”) diameter dispersion blade on a drill at a low to medium speed while adding water gradually. The coating will slowly return to a paste form as water is added during mixing. Continue to add water gradually while stirring until HPC® COATING becomes smooth, light, and fluffy and has the appearance of thick whipped cream. The amount of additional water that will be required will depend on the age of the coating and environmental conditions, but it can vary from one cup of added water to one to two quarts of added water. When properly mixed, HPC Coating will be a smooth paste that is wet to the touch and will adhere easily to the surface. It will not appear lumpy or dry when properly mixed.

| Late Stage During Mixing in Pail | After Proper Mixing / Ready to Apply |

Each pail of HPC® COATING must be mechanically stirred for at least three minutes just before spraying. It cannot be shaken or stirred by hand to reach the proper mix and texture.

HPC® COATING was designed to be sprayed using a conventional HOPPER GUN or a GRACO Texspray RTX 1000 - 1500 hopper feed texture sprayer. For small pipe, difficult access or small repair applications it can also be gloved or trowelled on.

Use a thickness gauge to check the wet thickness being applied. The number of coats and total thickness of the HPC® COATING will vary depending upon the desired results required and the application temperature ie. ambient temperature or operational temperature.

Whenever possible coat the entire surface one meter \ yard at a time. In the case of a pipe, start at the 12 o'clock position and spray a one meter length to the 6 o'clock position and then continue on the other side from the 12 o'clock to the 6 o'clock position for the same one meter length.

If a smoother surface for HPC® COATING is desired after application, use a wet, foam roller to lightly roll over the surface of the coating to obtain the desired smoothness.

OPERATIONAL APPLICATIONS - Applied directly to a surface temperature of between 200°F \ 93.3°C - 600°F \ 315.5°C. If the surface temperature exceeds 600°F \ 315.5°C and cannot be lowered within that range Contact Eagle for exact application instructions. Applications to a hot surface must be done with thin primer coats to steam the water out of each primer coat until the surface temperature settles down and stops doing the quick steam out of the coat -- usually two coats. Then the remaining mils WFT ( Wet Film Thickness ) can be applied to the required thickness needed. Allow to operate at the operational temperature overnight or for a couple of days and it is dry. This is multiple coat application.

NOTE - 1 mil = 1 thousandths of an inch 1/1000"

First apply a primer coat at 32 sf per gallon giving a thickness of 50 mils WFT or 38.5 mils DFT. Once the primer coats have finished steaming off, apply the desired mils WFT. Three nozzles are included with the machine and hopper gun. Use the small size ( 6mm ) nozzle. Adjust the airflow to the highest setting to start spraying the product onto the hot surface as the primer coat at 32 sf per gallon giving approximately 50 mils WFT or 38.5 mils DFT, to an in service heated pipe and allow to dry. This will only take a few minutes. Once the primer coat is complete, adjust the air pressure down to 60% - 75% to reduce the force of air and avoid blowing the product off while applying the build coat to the desired thickness. See Temperature Reduction Chart.

AMBIENT APPLICATIONS - Applied to a DRY non operating pipe or surface. Apply a primer coat at 32 sf per gallon giving a thickness of 50 mils WFT or 38.5 mils DFT. Allow the primer coat to set up for at least 8 hours @ 70°F \ 21°C. Then apply a build coat to the desired WFT.

NOTE : Allow each coat to dry between applications. Dry times will vary depending on the temperature of the sprayed surface. Applications done on non operational surfaces will need sufficient time to dry and firm up between coats. This time can be shortened by applying heat at 200°F \ 93.3°C and \ or air to speed the drying process. Apply heat for up to two weeks or as long as possible. All moisture must be evaporated from the coating before bringing the substrate to full operational temperature otherwise it may steam out causing bubbles and \ or knocking the coating off.

If a durable protective finish is required because of the surrounding environment, such as physical, mechanical abuse or over pipes subject to vibration, apply as follows. After the last coat is applied but before it dries, wrap polyester or fiberglass mesh around the pipe with the edges slightly overlapping to provide complete coverage. Allow this to dry. Topcoat with SUPERTHERM ®.

For exterior applications subjected to WEATHERING apply SUPERTHERM ® at 9 m2 \ 95 f2 per gallon giving 16 mils WFT or 250 microns \ 10 mils DFT or SP LIQUID MEMBRANE ® Water based aliphatic polyurethane at 18 m2 \ 200 f2 per gallon at 8 mils WFT or 92.5 microns \ 3.22 mils DFT. Allow to dry and cure over night.

For resistance from CHEMICALS apply ENAMOGRIP ® Solvent ( White or Coloured ) or RUSTGRIP ® at 18 m2 \ 200 f2 per gallon at 8 mils WFT or 92.5 microns \ 3.7 mils DFT. Allow to dry and cure over night.

For applications with HIGH HUMIDITY or SUBMERGED UNDER WATER allow the HPC® COATING to dry then apply EPOXOTHERM ® at 9 m2 \ 100 f2 per gallon giving 16 mils WFT or 312.5 microns \ 12.5 mils DFT. The total system can be submerged under water in two days. The full cure for the EPOXOTHERM ® is 10 days but in two days it has cured enough to allow for submersion while it completes its curing cycle.

IMPORTANT:

Do not take internally. Avoid contact with eyes. If solution does come in contact

with eyes, flush immediately with water and contact a physician for medical attention.

Avoid prolonged contact with skin or breathing of spray mist. For quickest removal

from skin, wash with water before drying.